THE ORACLE

THE ORACLE

Couldn't load pickup availability

The Oracle is another iteration from our micro drop concave. We made the deck smaller overall, mainly in width, to keep up with the narrow truck setups of modern day freeride and downhill. The drops come in at .25” and are paired with mellow tub concave, rocker, and flares. Pick up the Oracle today and get to surfing your local hills!

Collapsible content

SPECS

Length: 33”(83.82cm)

Width at Belly: 9”(22.86cm)

Width at Trucks: 8.5”(21.59cm)

Wheelbase: 22-24”(55.88-60.96cm)

CONSTRUCTION

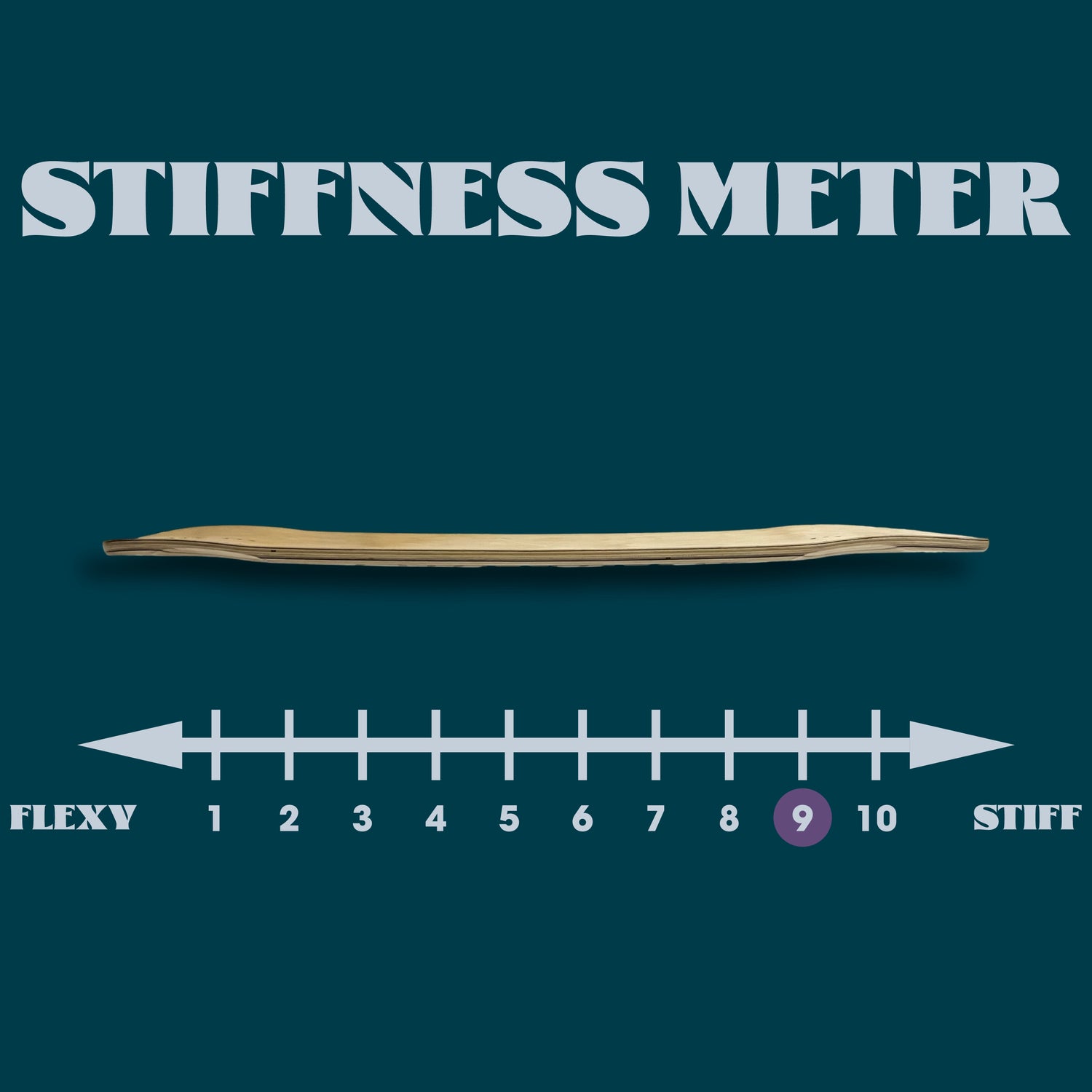

The Oracle is crafted out of 8 plies of hard rock Great Lakes Maple and one layer of custom weave 9 ounce Triaxial Carbon Fiber and one layer of 13.8 ounce Triaxial Carbon Fiber.

ABOUT FOSTER BOARDS

MATERIALS

All of the materials we put into our boards are aimed at being as sustainable as possible.

-The Wood is sourced from a sustainable mill

-The Glue used in our boards is a water based PVA glue for lowest environmental impact

-The Resin used is 29% bio based resin called SuperSap by Entropy Resins

-The Inks used in our graphics are water based acrylic inks, significantly less toxic for the environment than the oil based inks used by most in the industry

-The Lacquer used to seal our boards is a waterborne lacquer with extremely low VOC content which leads to less impact on the environment.

GRAPHICS

All of our graphics are hand screen printed in our shop in Seattle, WA.

They are printed using high quality water based inks. Because they are screen printed by hand, slight variations might be present in each board.

All Graphics are created by Gerry Kreuder with a collaboration of ideas from the team.

PROCESS

All of our boards are made from start to finish in our shop in Seattle, WA.

We have strict quality control rules in place throughout the process to insure each and every board that leaves our shop is of the highest quality.

Our CNC machine and programming is able to process material with accuracy better than .001” which guarantees 100 percent accurate boards and specs every time.