THE FINGY V1

THE FINGY V1

Couldn't load pickup availability

Collapsible content

SPECS

Length: 36”(91.44cm)

Width: 8”(20.32cm)

Wheelbase: 22”(55.88cm)

CONSTRUCTION

The Fingy is crafted out of 7 plies of hard rock Great Lakes Maple.

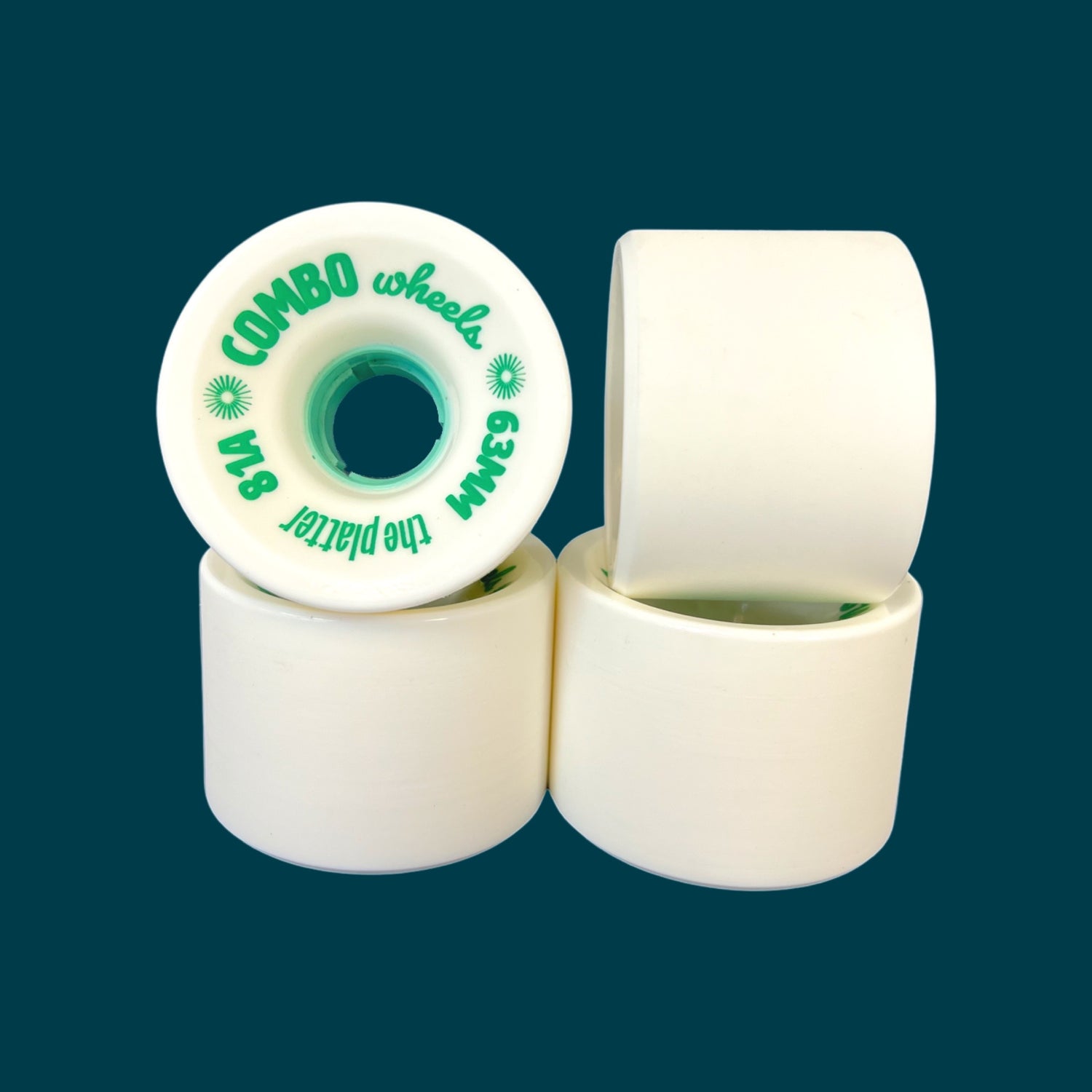

COMBO WHEELS: THE PLATTER

The Combo Platter is the perfect choice in a wheel for the Fingy Complete. It has great edge grip for hard carves but also provides an amazing slide for slashing around town surf style. With these two characteristics paired with its extremely fast roll speed, the Platter completes the vibe we were going for with the Fingy complete. Combo wheels are poured in the USA in a premium urethane formula.

ACE TRUCKS: CLASSIC 22’S

We chose Ace Classic 22’s for The Fingy Complete because they have the best turn out of any TKP truck we have ridden. Paired with Riptide bushings, these trucks are carve machines and a perfect paring with The Fingy’s flexibility and rebound.

ABOUT FOSTER BOARDS

MATERIALS

All of the materials we put into our boards are aimed at being as sustainable as possible.

-The Wood is sourced from a sustainable mill

-The Glue used in our boards is a water based PVA glue for lowest environmental impact

-The Resin used is 29% bio based resin called SuperSap by Entropy Resins

-Basalt and Fiberglass are consider the most sustainable of all reinforcement fabrics. Basalt Fabric is made from Basalt or more commonly know as lava rock. Fiberglass is mainly made from sand something that is very abundant.

-The Inks used in our graphics are water based acrylic inks, significantly less toxic for the environment than the oil based inks used by most in the industry

-The Lacquer used to seal our boards is a waterborne lacquer with extremely low VOC content which leads to less impact on the environment.

GRAPHICS

All of our graphics are hand screen printed in our shop in Seattle, WA.

They are printed using high quality water based inks. Because they are screen printed by hand, slight variations might be present in each board.

All Graphics are created by Gerry Kreuder with a collaboration of ideas from the team.

PROCESS

All of our boards are made from start to finish in our shop in Seattle, WA.

We have strict quality control rules in place throughout the process to insure each and every board that leaves our shop is of the highest quality.

Our CNC machine and programming is able to process material with accuracy better than .001” which guarantees 100 percent accurate boards and specs every time.